Do You Need to 100% Glue Down the Turf In Your Indoor Facility or Batting Cage?

Published March 19th, 2024

“The problem with 100% Gluing Down Turf is that it makes the removal and replacement at the end of life a very difficult, messy and expensive process. Avoid it when possible.”

The answer is, No. Probably Not. There are better ways to do it.

We get this question frequently because many indoor facilities have done this in the past. This turf installation method was very common because older style “AstroTurf”f fields were, and Outdoor Nylon Field Hockey fields still are, 100% glued to a rubber pad underneath it.

That type of “flat” turf is not heavy enough to lay by itself without a pad. You see this same kind of turf in many cages and facilities who want this “flat” carpet-style turf but is it really necessary to glue it down 100% in much smaller spaces such as batting cages and indoor facilities?

Infill Turfs and Padded Turfs are heavy enough to lay themselves and absolutely do not need to be glued 100%. Heavier ounce face weight turfs can be spot glued strategically. Lighter ounce turfs with no pad or infill can also just be spot glued in batting cages and smaller facilities.

The ATX Turf team has put together a list of advantages and disadvantages of each.

Reason for 100% Glue Down Turf Installations

- Lighter Weight Turf Won’t Move

- Ensures Against Wrinkling Over Time

The main idea is that a 100% glue down will prevent wrinkling in your turf over time and your seams may hold longer, “IF” it is even thoroughly, and truly 100% glued down. This depends on your installer.

Reasons NOT to 100% Glue Down Turf in Batting Cages

- End of Life – Removal Headache Nightmare

- Better Ways to Prevent Wrinkles

- Wrinkles can be Fixed Even if They Occur

- Netting & Other Equipment Hold the Turf Down

- Floor Repair

- Turf Can’t Be Re-Used

- End of Life Nightmare

We took pictures of the last 100% Glue Down Turf removal we did to document what happens in the long run with 100% glue down jobs. This was a 9,000 sq ft facility which had a flood and the turf “could” have been salvageable and repurposed but was ruined due to the 100% glue down process.

While it only took us 2 days to install the new turf, it took 3 days of scraping with a bobcat and half a pallet of Acetone to remove the previously, 100% glued down turf.

2. Better Ways to Prevent Wrinkles

Seasoned turf installers know that turf expands and contracts with temperatures and a turf which wasn’t allowed to rest very long and was installed in the winter, can grow several inches by the summertime. If the edges or seams were glued to the floor before proper resting, you can very well see wrinkles start forming in the first year.

Ideally, there is enough time for turf to rest. During the installation process, it’s a good idea to even grab the rolls by the ends and “wave” it a bit to

The point here is, if you can allow enough time during the installation, you don’t have to worry about wrinkles as much down the road, and therefore, you don’t need to 100% glue it down.

3. Wrinkles can be Fixed Even if They Occur

4. Netting & Field Equipment Hold the Turf

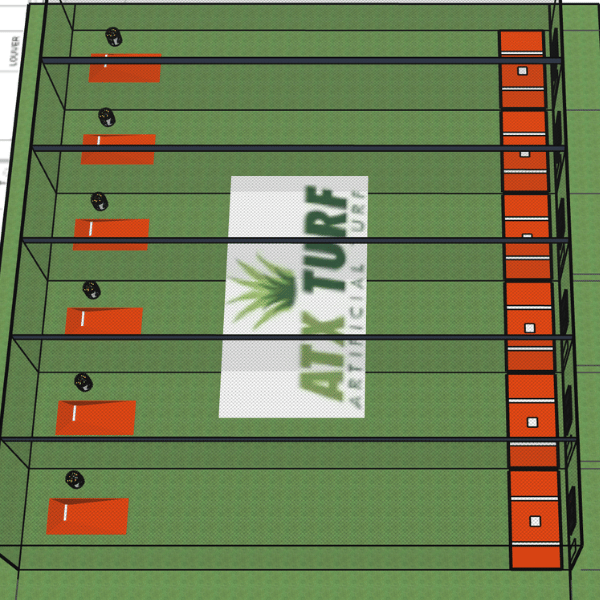

The other thing to consider in batting cage facilities, is that the netting support system itself may secure the turf. Some nets have a weighted rope border at the bottom which lay on the turf. Sometimes you’ll see facilities with vertical cables running from the ceiling and anchored through the turf and into the floor. More advanced systems may have cable running along the ground around the perimeter and the net is hog-ringed or clipped to this “base” cable. In some facilities, you’ll see sand bags in the corners or along the edge of the net to hold the netting in place.

In these cases, You may not need ANY Glue (except the seams) because the netting system or sand bags are actually securing the turf in place.

5. Floor Repair

6. Turf Can’t Be Re-Used or Re-Sold

The turf is not salvageable. This pile of turf is the result of having to scrape the turf off the concrete floor. Even the partial rolls that came up will never lay down flat due to the glue on the back constricting and creating permanent wrinkles. In many facilities, parts of the turf still have a lot of life left in them and can be sold on the secondary market for close to $1.00 sq ft. If the turf has been glued down 100%, this is not doable.

Finally, How Long Will the Turf Be In Your Facility Anyway?

It might seem that the removal is a long way off and the removal will be somebody else’s problem. While the warranty on our turf is 12 years, many cages and facilities will never be around as long as full fields at schools. Commercial leases for warehouse spaces are often 3 to 5 years, facilities grow and want to move to bigger spaces, or they go out of business. Backyard Cages, Basements and Garage Cages are often repurposed after the kid goes off to college in 5 years or you want to move and someone needs the garage space.

Even schools, which typically don’t go out of business or move, even need to repurpose a space, replace turf due to flooding or simply want to upgrade the turf long before its life is over.

So before gluing your turf down 100%, consider the ramifications of gluing a material in such a large space. At minimum, you can start out by simply loose laying the turf, you can always add more glue later if you need to.

If you have any more questions on turf installation or the best way to secure your turf, reach out to an ATXTurf Rep at 866.428.2809

0 Comments