Should I buy Used Artificial Turf?

Published, August 8, 2022 / Updated July 21, 2023

“Remember to always ask your Used Turf Supplier for Manufacturer & Specification Sheet so you know who made it, how old it is and the materials used in it. “

Used Artificial Turf is often a fine alternative to new Artificial Turf. As more and more turf fields come up on their warranties, more fields are removed each year. While there is no shortage of used turf anymore, there is a shortage of quality used turf with life still in it.

There are number of issues to consider when buying used artificial turf. This article will discuss the following:

How old was the turf?

What size are the rolls of used turf?

Can I seam Used Turf Rolls back together?

Will there be lines in my Used Synthetic Turf?

Can I get All Green Used Turf?

What are other hazards of used turf?

Will my Used Synthetic Turf have Rubber Infill?

How old was the turf?

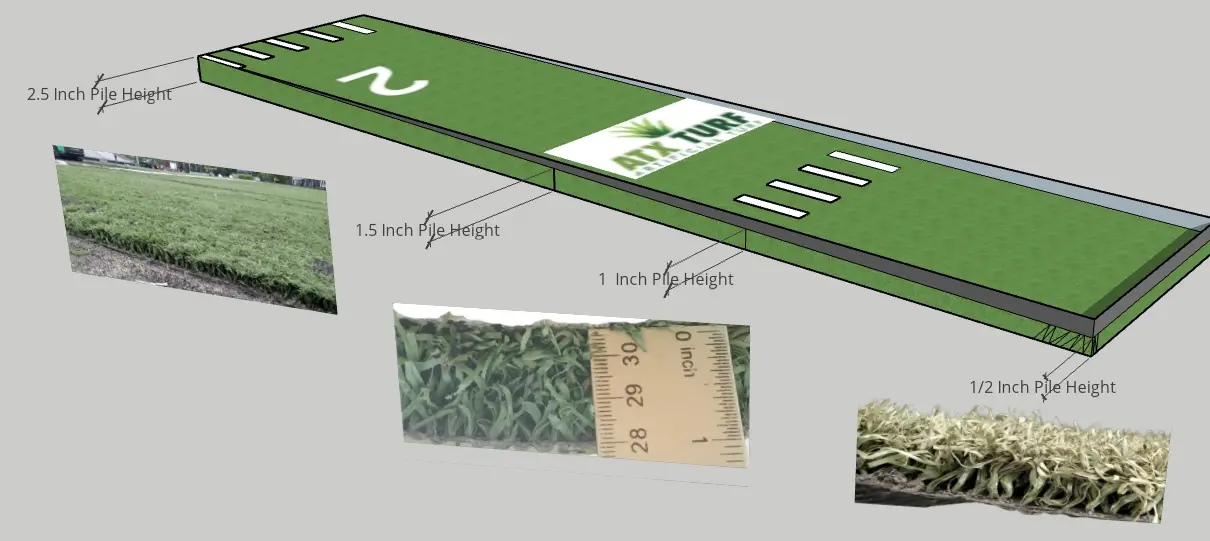

As turf wears, the tips of the fibers begin to fray and breakdown over time. Many fields begin with a 2.25 or 2.5 inch pile height but the wear of cleats and general foot traffic over the years, breaks down the fibers. Many older fields with excessive wear, that are passed their warranty, may often only be 1 inch thick, or even worn down to the nub in the highest trafficked areas. When purchasing used turf, its important to ask how old the particular turf might be.

What size are the rolls of used turf?

Various machines and methods are used to remove turf athletic fields and indoor facility turf. It’s often cut at the origins seams, in which case, they will be 15 ft wide. Other machines may cut the rolls in half at 7.5 feet, while other machines cut them at 10 ft or even only 4 feet wide. While smaller rolls are lighter in weight and might be easier to handle, the downside is that it will require more seams when reinstalling the turf. For example, if your area is 30 feet x 70 feet wide, 2, 15 x 70 foot rolls will only require 1 seam down the middle. However, if you purchase 4, 7.5 x 70 foot rolls, you will have 3, 70 foot seams running the length of your area. Not only does this require more labor and materials during the installation process, but also creates more variables down the road as the turf wears further.

Can I seam Used Turf Rolls back together?

Inconsistencies in Blade Height

Yes, but it can be tricky. This depends on how carefully the turf rolls were removed from their original home. Some devices separate the rolls at their original seams, where turf glue and seaming fabric will still be stuck to both edges of the rolls. Seam fabric and glue can be thick, so the idea of adding another layer of seam fabric and glue is not ideal, as your seams

The other variable is whether the edges were cut straight upon removal. Some turf companies will use concrete saws or other blades to run down the field, but in these cases, it is highly unlikely that the blade remains in the same tuft row and will zig zag back and forth. In the case of reinstalling used turf rolls like these, you will need to recut the edges, so as to have 2 straight edges to seam together. This will also make the rolls smaller in width, so your 15 ft roll may become a 13 or 14 ft roll.

Varying pile heights is also an issue when attempting to seam together used turf rolls. 160 ft wide football fields are often cut down the middle to create 80 ft rolls, or into thirds, to create 53 ft rolls. Athletics fields see the most wear in the middle of the field, so on a 7 year old field, the pile height in the middle may be 1 inch, while the pile height towards the sidelines may still be 2 inches. Rolls in the middle of the field may wear faster than rolls closer to the endzone, while the rolls on the sidelines and Dzones may have hardly any wear. While you may have 2 rolls of turf, technically from the same field, this does NOT mean they will seam together well. Unless the 2 rolls you are seaming together were next to each other on the original field, you are highly likely to have 2 rolls of turf with VERY different pile heights, creating awkward seams with one side being taller than the other, which is a tripping hazard and safety issue.

Football yard numbers, logos and endzone pieces can be particularly challenging when reinstalling as used turf. Upon the initial installation, these were cut into the full, green pieces of turf and glued in with seam fabric on the back. It can often be difficult to reinstall these rolls because you may have wrinkles around the numbers and logos that did not exist on the original field. When the original field was installed, the panels were glued or sew together and “stretched” before cutting in these pieces, when the seams are cut up removal, the rolls “contract” since they are no longer stretched by the adjacent, attached rolls, frequently creating funny wrinkling around the inlaid numbers, logos and lettering.

Will there be lines in my Used Synthetic Turf?

Most likely, Yes. If the used turf came from an outdoor athletic field, it will most likely have some inlaid lines, where the actual fibers are a different color than green. Some fields are made of all green turf and the lines are simply painted on, which often fade over time. As most used turf comes from recreational, high school and college athletic fields, the yard lines

Can I get All Green Used Turf?

It is possible to find all green used turf, but it is rare. If a former field was only used for soccer, there are larger portions of all green from those fields, as opposed to football fields. The outfield of baseball fields is typically all green and even larger football fields with wider sidelines and Dzones will often have a handfull of all green rolls. If the fields are inside of a track, however, these rolls are often curved at one end, due to the oval shape of the track. Former indoor sports facilities, training facilities and batting cages will sometimes have all green turf, as well, and if they close or replace their turf, all green rolls might be available. These are rarer and typically sell faster, at a premium.

What are other hazards of used turf?

Used Synthetic Turf can often have other foreign objects not found in new turf. While some used turf has been cleaned, it is often not cleaned. The rolls are simply rolled up from the original field with mouth guards, bandaids, broken glass, gauze tape, bubble gum and any number of other unsanitary items. But another common occurrence is rusty nails.

Will my Used Synthetic Turf have Rubber Infill?

Some types of turf require rubber pellets, called “Infill” and other types do not. Most outdoor athletic fields have crumb rubber which is what provides the “impact attenuation” or, cushion to prevent injury. When these fields are removed, sometimes the crumb rubber is sucked out before removing the actual turf rolls and sometimes the rolls are rolled up with the rubber still in it. It’s possible the crumb rubber may also be removed at a later time. Either way, its nearly impossible to extract all of the rubber infill. If the used turf you purchasing came from these fields, its most likely to have some rubber infill to some degree, in some cases weighing up to 8 lbs per sq ft.

Contact a Rep at ATXTurf today to discuss the life expectancy of your Turf for your application. 866-428-2809

0 Comments